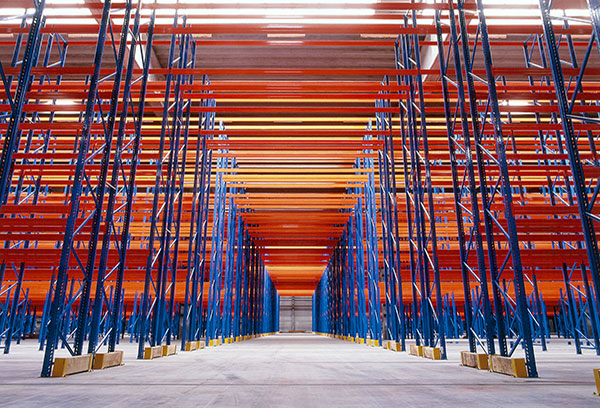

Rack Safety Training

The applicable legislation relating to Safety Inspection of Racking is; The Safety, Health and Welfare at Work Act 2005, Chapter 1 General Duties of Employers, Section 8, subsection c (iii) to provide a safe place of work. SI 299, 2007 General Application Regulations (Chapter 2, Section 30 and 31) require that work equipment is maintained and checked periodically.

The Health & Safety Authority classifies all types of racking and storage equipment as working equipment. No actual time scale is set down in the legislation as some types of equipment may need daily inspection and some may only need inspection every 2 years. For Storage equipment, further guidance is given by the Health & Safety Executive (UK) in their booklet HSG76 on storage and warehousing, paras 631-654. Here it states that racking should be inspected at intervals of not greater than 12 months by a competent person. A competent person is defined as, a trained specialist within your own organization, a specialist from the rack supplier (manufacturer) or an independently qualified racking inspector e.g. S.E.M.A. Approved Racking Inspector. (Storage Equipment Manufacturers Association)

In addition to S.E.M.A. approved rack inspections, All Storage Providers recommends that companies train it’s employees to a level whereby employees can conduct “in-house” inspections on a more frequent basis – weekly / monthly depending on the type of organisation, the business and the type and frequency of issues found.

Racking Inspection Training Course

All Storage Providers provide a Racking Inspection Training Course using a S.E.M.A. Approved Racking Inspector as follows;

- Course Duration: 1 day

- Start Time: 1000hrs

- Finish: 1600hrs

- Max No of Participants: 10

Course Content

- 1: Introduction to rack safety and need for rack inspections

- 2: Types of inspection, frequency, records to be kept and action points arising from survey

- 3: Responsibilities of: - everyone - original supplier - the user

- 4:Damage Levels

- 5:Drive-in and Cantilever Racking

- 6:Damage prevention

- 7:Action on serious incidents

- 8:Review of literature

The training will include referral to actual samples of damages as well as a perfect example of an upright. We also recommend, for on-site courses, a practical demonstration, in the warehouse, on measurement of beam deflection.

Contact Us today for more information on Rack Safety Training

Contact Us